Assembly Line Analytics: Transforming data to business insights and actionable outcomes

Digital & Technology

359 week ago — 5 min read

Summary: Assembly Line Analytics insights can be used to improve production speed for large manufacturing organisations and can thereby add exponential value to the business.Lester Fernandes explains how.

Every organisation today is facing the need for quick conversion of its valuable data (usually in large volumes, significant variety, rapid velocity and probabilistic veracity – the unique characteristics of big data). It is imperative to quickly capitalize on insights from the data and translate it to favourable outcomes that delivers incremental or sometimes exponential value to the business and its processes. But, how do we industrialise the analytics factory and churn out business insights and outcomes in a predictable manner?

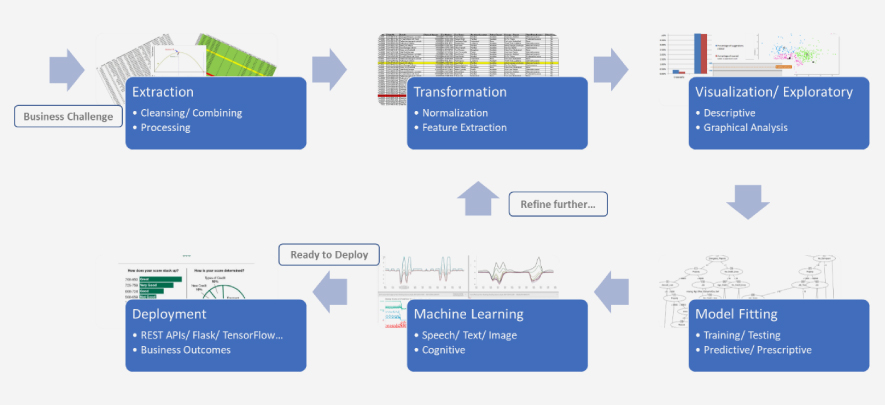

We refer to an industrialised solution as the assembly line for achieving these insights from analytic outcomes at rapid speed – a single business problem with the related data and insights/ outcomes achieved within a matter of weeks. The insights and outcomes themselves could lead into related or smaller business problems that can be further addressed within a similar process chain. This can be considered similar to what Thomas H. Davenport visualized within “Creating value in the Data Economy” in his article “Analytics 3.0” in HBR (Harvard Business Review).

An organisational construct for meeting this objective is an Analytics Centre of Excellence (CoE) that is subdivided within into the process-based steps and knowledge experts fluidly moving across boundaries. This approach allows for specific domain knowledge experts to internalise the business problem and related data as inputs to every stage and subsequently architect significant value and further insights to every subsequent stage. As long as there is a pipeline of business problems requiring similar analysis, each work unit is efficiently engaged and able to proactively engineer progress based on work scheduling factors within the analytics projects’ pipeline.

This approach can be likened to moving forward at optimal pace considering the “Theory of Constraints” principles given the limit on availability of critical knowledge experts – it allows to maximise throughput and achieve efficiency in operations. The iterative process at subsequent stages within the assembly line further leads to getting the best quality integrated knowledge to effectively address the Data Science and technology acumen perspectives along with the business understanding that is essential to tailor a practical and workable analytics solution.

Architecting the entire process as an assembly line embodies the thoughts outlined by Gerald C. Kane of MIT SMR (Sloan Management Review) in his blog "Common Traits of the Best Digital Leaders". The key elements that have been outlined within the 4 step process and their relevance to the analytics assembly line:

- Direction: The Assembly Line provides the end vision and purpose towards the articulated business insights & outcomes

- Innovation: Clearly demarcating the expected deliverables for each stage creates the conditions necessary for people to experiment and innovate

- Execution: With clarity on expected outcomes, the knowledge architects are further empowered to think differently within the time constraints of the overall assembly Line

- Collaboration: Rotation of the knowledge architects across roles within the assembly line is a strong motivator to collaborate across boundaries for different business problems

Modelling the analytics function as an assembly line is instrumental for business to quickly reap the speed, value and quality benefits. Ensuring that the analytics portfolio within digital transformation is primed with newer business challenges ensures that knowledge architects are continuously motivated in a virtuous cycle towards more valuable insights with quicker outcomes.

References:

1. Thomas H. Davenport “Analytics 3.0” from Harvard Business Review December 2013 issue

2. Eliyahu Goldratt’s “The Goal” and the Theory of Constraints

3. BUDSTA© – The Integrated Framework for Analytics Solutions

4. "Common Traits of the Best Digital Leaders" Gerald C. Kane MIT SMR Digital Leadership Blog

To explore business opportunities, link with me by clicking on the 'Invite' button on my eBiz Card.

Disclaimer: The views and opinions expressed in this article are those of the author and do not necessarily reflect the views, official policy or position of GlobalLinker.

Posted by

Lester Sebastiao FernandesI am looking to connect with other business owners who need to extract analytical insights from current data and take informed decisions. We make your Data Insights journey easier...

Network with SMEs mentioned in this article

View Lester 's profile

Other articles written by Lester Fernandes

Technology & business trends: 2019 & beyond

343 week ago

Most read this week

Comments (2)

Share this content

Please login or Register to join the discussion